Everything You Need To Know About UV Printing On Acrylic

Modern technologies have made it possible for us to print on almost any surface, and UV printing on acrylic is a beautiful addition to this unique process. This transformation of printing gives us a new perspective on interior design and the exterior due to his vibrant ink over versatile Acrylic surfaces.

If you need eye-catching signs, sleek photo frames, or custom artwork, UV printing on acrylic delivers unbeatable quality and variety. Let us break down the elements of UV printing on acrylic, its process, its many benefits, and some applications to help you decide if this is something for your next digital print. So, let’s get started!

What Is UV Printing?

UV printing is a way to allow digital printing with the help of ultraviolet light, which instantly turns or dries the ink. Traditional printing needs heat or solvent to dry the ink, whereas UV light quickly cures it once it strikes. Some post-processing time is invested in this, leading to quicker production times. This printing is ideal for non-porous substrates like acrylic and guarantees a colorful, durable graphic.

Why Choose Acrylic For UV Printing?

Acrylic, or polymethyl methacrylate (PMMA), is a durable and versatile material commonly used in numerous applications such as signage, displays, and artwork. Its properties make it an ideal medium for UV printing:

- Durability: Acrylic is highly resistant to impact, water, and UV light, which makes it ideal for both indoor and outdoor applications.

- Clarity: Acrylic offers excellent transparency and can showcase vivid colors beautifully.

- Versatility: It can be shaped and produced in various thicknesses, enabling multiple uses.

The UV Printing Process On Acrylic

Understanding this printing process on acrylic is crucial to appreciating its benefits and applications. This process transforms plain acrylic sheets into stunning visual pieces through several detailed steps.

1. Preparation:

Before the printing can begin, the acrylic surface must be meticulously prepared. This involves thoroughly cleaning the acrylic to remove dust, oils, or contaminants, ensuring the inks adhere correctly. A clean, smooth surface is essential for achieving flawless prints.

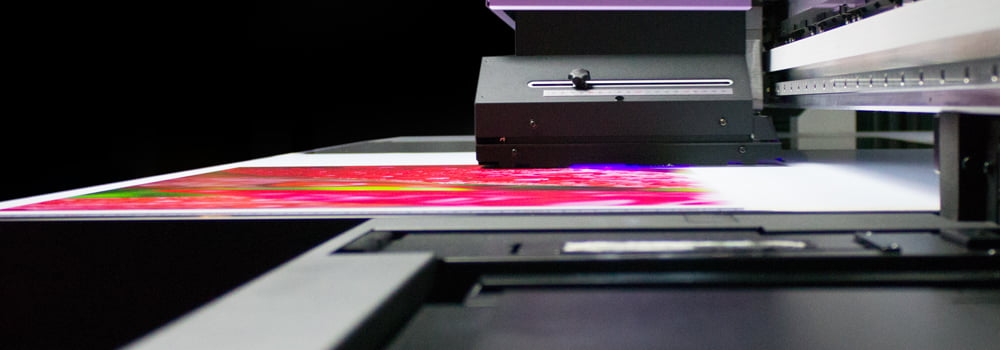

2. Printing:

Once the acrylic is prepared, the digital file is sent to a UV-curable inkjet printer. This printer uses UV inks specially formulated for non-porous surfaces like acrylic. The printer head deposits tiny ink droplets onto the acrylic surface, and UV light instantly cures the ink. This rapid curing process prevents smudging and ensures high-resolution, sharp, and vibrant prints.

3. Curing:

As the ink is deposited onto the acrylic, it is immediately exposed to UV light. This instant curing process solidifies the ink and bonds it with the acrylic surface, resulting in durable prints that resist fading. The hardened ink creates a long-lasting bond with the acrylic, making the prints ideal for indoor and outdoor use.

4. Finishing:

After printing and curing, the acrylic may undergo additional finishing steps such as cutting, drilling, or polishing. These steps are essential for obtaining the desired final product and enable high customization. For instance, shaping the acrylic into specific forms, drilling holes for mounting, or polishing to achieve a smooth finish can significantly enhance the print’s visual appeal.

Advantages Of UV Printing On Acrylic

UV printing on acrylic offers numerous advantages, making it an ideal choice for various applications. From vibrant, high-quality prints to eco-friendly processes, the benefits are manifold.

- Vibrant, High-Quality Prints: It produces high-resolution images with vibrant, true-to-life colors. The UV-curable inks adhere well to acrylic, ensuring sharp and vivid prints resistant to fading and smudging. This makes them perfect for long-lasting signage and art pieces.

- Durability: Acrylic is known for its durability, and UV printing enhances this by creating a strong bond between the ink and the acrylic surface. This produces prints that are highly resistant to fading and wear, making them suitable for indoor and outdoor use.

- Versatility: It can be applied to various thicknesses of acrylic, from thin sheets to thick blocks. This versatility allows multiple applications, including signs, displays, photo frames, awards, and custom art pieces.

- Eco-Friendly Process: This process produces less waste and emits fewer volatile organic compounds (VOCs) than traditional methods. UV inks are free of harmful solvents, making them safer for the environment and handlers.

- Customization and Flexibility: It allows for high levels of customization, enabling the creation of unique designs, logos, and images on acrylic surfaces. This flexibility benefits businesses needing customized promotional materials, corporate gifts, or branded signage.

Applications Of UV Printing On Acrylic

UV printing on acrylic offers versatile, high-quality solutions for various applications due to its vibrant colors, durability, and high-resolution capabilities. Here are some of the most popular uses:

- Interior Design: Acrylic prints are widely used in interior design to create vibrant, eye-catching elements. UV-printed acrylic, whether used for wall art or photo frames, brings a modern and elegant element, elevating the aesthetic appeal of any environment.

- Signage: Printing on acrylic is ideal for creating durable, weather-resistant signs that maintain their quality over time. These bright, durable signs suit indoor and outdoor settings, making them a dependable option for businesses and public areas.

- Corporate and Retail Displays: Retail stores and corporate offices often use UV-printed acrylic for displays and promotional materials. The prints’ clarity and vibrancy help attract attention and effectively convey messages, enhancing customer engagement and brand visibility.

- Art Pieces: Artists and designers use UV printing on acrylic to create unique, striking art pieces. The high-resolution images and rich colors make acrylic an ideal canvas for modern artwork, allowing precise reproduction of intricate details.

- Awards and Plaques: Acrylic is also used to create customized awards and plaques. Its durability and elegance make it a preferred choice for recognizing achievements and milestones, and high-quality prints ensure lasting impressions.

Maintenance Tips For UV Printers For Acrylic

Maintaining your UV ink printer for acrylic is crucial for longevity and high-quality acrylic prints. Regularly clean print heads and surfaces to prevent clogs and perform nozzle checks for smooth operation. Use high-quality UV inks and scratch-free acrylic sheets for vibrant, durable prints, and store materials properly.

Follow the manufacturer’s maintenance schedule, replace worn parts, lubricate components, update firmware, and periodically calibrate and align the printer. These steps ensure consistent, high-quality prints, optimal performance, and a longer printer lifespan, providing a better return on investment.

FAQs

Acrylic is naturally UV-resistant, experiencing only about 3% degradation over ten years in outdoor use. It is also scratch-resistant, making it ideal for long-term applications.

Yes, neon acrylic paint glows under black light. The fluorescent pigments absorb UV light and emit visible light, making them suitable for black light applications.

Final Words:

UV printing on acrylic offers vibrant, durable, and versatile prints for various applications, from interior design to corporate displays. Understanding the process and benefits helps you maximize this technology. At Artplus, we provide top-notch UV printing services, delivering high-quality prints that stand out. Explore our services to bring your designs to life with UV printing on acrylic.