Ever wondered about your wall’s striking pattern? Wallpaper printing is the alchemical process that turns a flat file into a textured reality. This ancient craft enjoys a global renaissance today. People demand custom wallpaper printing designs and highly personalized wallpaper for homes. We’ll demystify this entire creative journey for you right now.

The process starts with traditional handcrafting before advancing to contemporary digital production systems. The course provides essential knowledge about materials and ink selection and quality standards, which are vital for producing high-end interior wallpapers. The complete masterclass experience will deliver an unforgettable learning experience that you will never forget.

1. The Traditional Art: Hand-Block and Surface Printing Methods

The traditional methods produce outstanding visual depth, which contemporary machinery struggles to achieve. Understanding these foundational processes is vital for appreciating the whole spectrum of textured wallpaper options available. They truly add depth and character to walls.

These older techniques feature a slow production rate, but they yield pieces with a totally inimitable character. They cannot compete with industrial solutions for speed, but their heavier ink laydown remains popular. This artisanal texture is highly desired for truly elegant and modern home décor. It reflects your style and personality perfectly.

A. Block Printing (The Artisan Method)

Block printing stands as the original method from which all wallpaper printing techniques descended. Artisans with expertise use thick wooden blocks which they hand-carve to transfer their designs. The lengthy production method results in walls with organic flaws and textured appearance. The traditional method enables designers to create genuine heritage patterns that suit interior wall decoration.

B. Surface Printing (The Mechanized Classic)

Surface printing introduced a major advancement in automation through raised metal rollers, which enabled fast, continuous pattern production. This excels at high-speed, large-volume runs of traditional patterns. However, it usually yields a much flatter, less tactile surface compared to block printing.

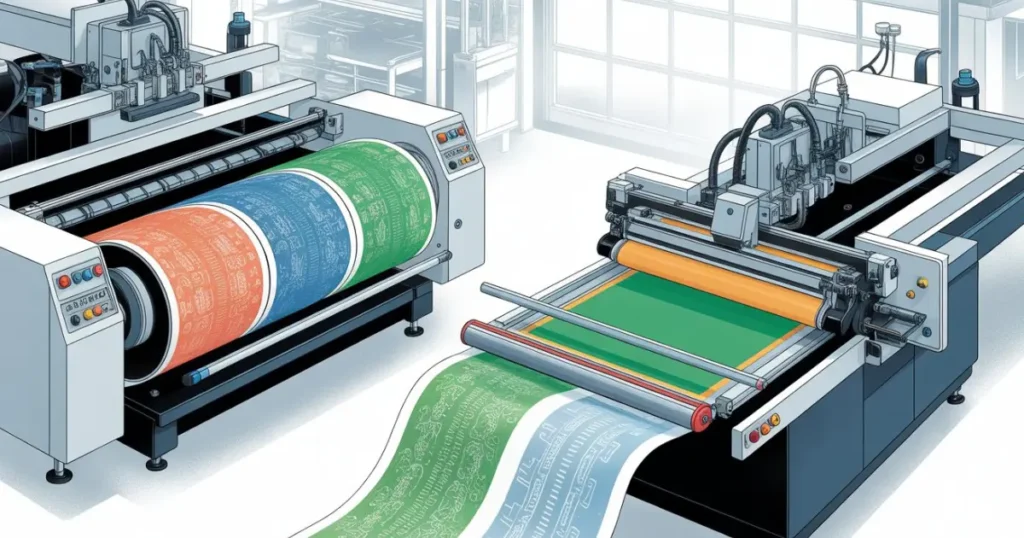

2. The Workhorses: Rotary and Flat-Bed Screen Printing

Screen printing holds a vital mid-ground between slow manual work and rapid industrial titans. This venerable technique guarantees a robust ink laydown, producing highly saturated colors and a unique texture. For projects needing vibrancy and moderate volume, this method is the optimal compromise for commercial wallpaper printing. It can truly transform interior spaces.

These screen techniques prove remarkably versatile, handling various substrates effortlessly. They allow heavier ink deposits than many processes creating a real three-dimensional quality you can feel. Screen printing remains a cornerstone of quality decorative wallcovering production. It helps to enhance room ambiance significantly.

A. Flat-Bed Screen Printing

The flat-bed process operates as a large squeegee tool which forces ink through a mesh stencil to print onto stationary materials. The process delivers exact color alignment which makes it suitable for intricate large-scale designs and geometric patterns.

B. Rotary Screen Printing

The production process becomes faster through Rotary screen printing because it operates with continuous cylindrical screens that maintain constant motion. Ink pushes from inside the cylinder creating a remarkably swift seamless design application. This mechanism is perfect for high-speed non-stop pattern runs in Wallpaper Printing UAE. It provides Expressive interior styling for large projects.

3. Industrial Powerhouses: Understanding Gravure and Flexographic Techniques

When your project demands massive volume and perfect consistency these two industrial giants enter the arena. Gravure and Flexographic printing are the industry’s behemoths capable of producing millions of linear meters very quickly. They fundamentally revolutionize mass wallpaper fabrication. These methods are key for Home and office wallpapers stock.

These high-speed processes drastically cut the per-unit cost of wallcoverings. This makes decorative finishes accessible to the broader market. If you source stock for big Commercial wallpaper printing orders you must understand their specialized abilities. Their defining trait is incredible production efficiency you can count on.

A. Gravure Printing (Rotogravure/Intaglio)

Gravure printing uses copper cylinders engraved with tiny ink-holding cells called intaglio. The cell depth controls the exact ink volume transferred onto the paper. This allows for exceptional photographic detail and seamless tonal transitions. It guarantees unmatched color consistency across huge print runs perfect for Living room wallpaper themes.

B. Flexographic Printing (Flexo)

The flexo process uses flexible photopolymer plates which wrap around a cylinder to create designs that transfer to substrates through a modern stamping method. The process provides fast and affordable production for basic design work and standard wallpaper materials. The Flexo process operates with complete success on all types of surface textures.

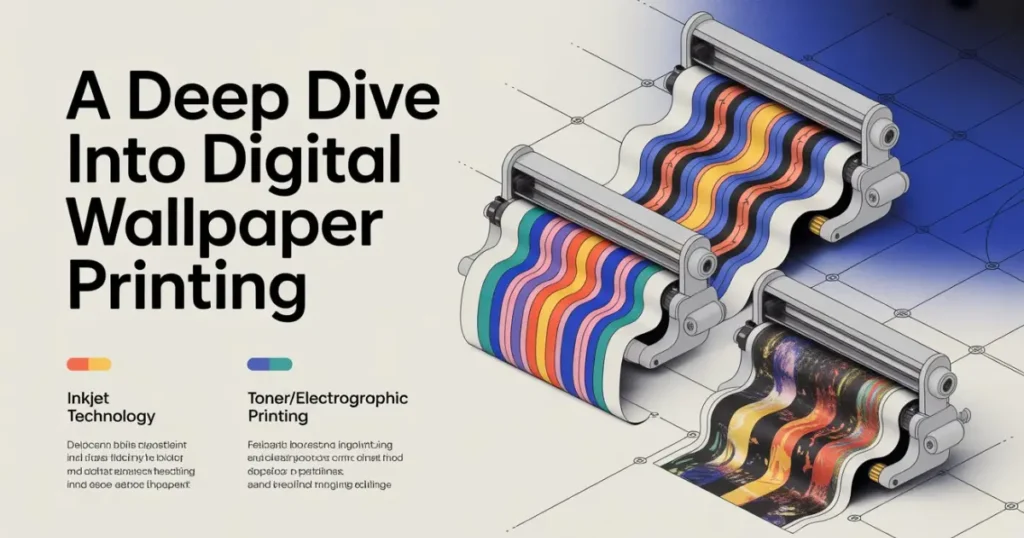

4. The Custom Revolution: A Deep Dive into Digital Wallpaper Printing

This is the modern digital era in which users can create personalized wall murals in the exact size of their walls with the help of digital technology. The digital revolution has given a tremendous boost to creative development and that is why the wallpaper printing industry in the UAE is developing rapidly. Thanks to modern digital tools and printing technology, customers can create unique and creative wallpaper designs, which gives them the opportunity to make the interiors of their homes completely unique by decorating them according to their personality and tastes.

A. Inkjet Technology

The process of modern inkjet digital printing uses wide-format machines to precisely place micro-droplets of ink onto materials. These machines primarily use eco-friendly Latex or highly durable UV-cured inks. Inkjet requires zero setup time and provides unparalleled detail resolution for Modern wallpaper trends.

B. Toner/Electrographic Printing

Toner-based printing uses charged particles and heat to bond the pigment onto paper substrates like a professional copier. While less common for long continuous rolls this electrographic technique is great for highly specialized short-run custom wallpaper designs. This process guarantees brilliant sharp graphical output every time.

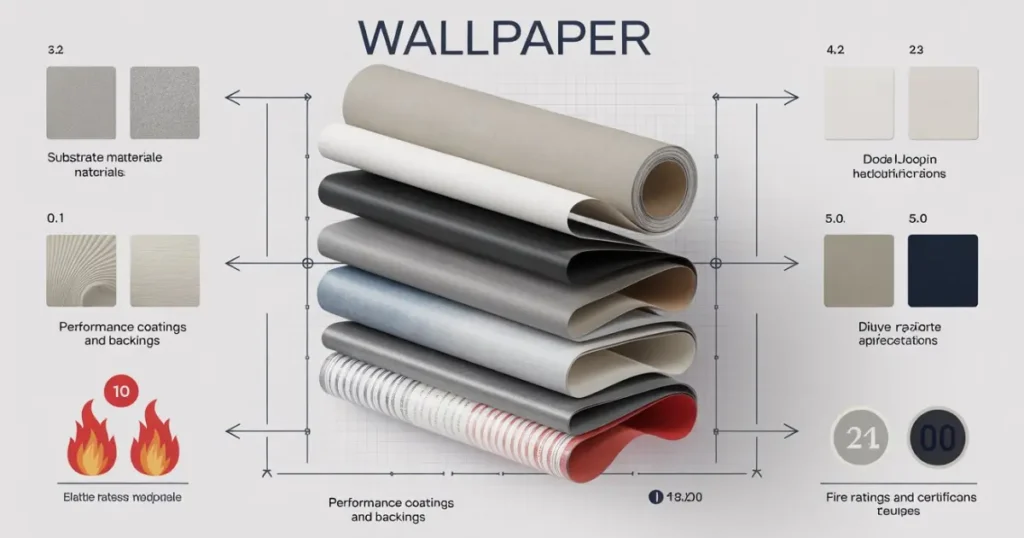

5. The Foundation: Choosing Substrates and Performance Coatings

The wallcovering quality depends equally on design elements and the substrate which functions as the base material. The final appearance of Wallpaper printing services depends entirely on the substrate material which serves as the printing surface. Your entire interior design concept will fail when you select an inappropriate material for your project.

The Wallpaper Printing UAE market requires materials that demonstrate exceptional resistance to heat and humidity because of its demanding climate. Performance coatings function as essential protective barriers which defend against environmental degradation. The investment in Long-lasting wall decoration will extend its lifespan through decades because of these protective coatings. Your selection should always focus on materials which provide the longest possible service life.

A. Substrate Materials

We divide substrates into three main types Vinyl non-woven and paper each with a different set of features. Vinyl provides supreme washability making it ideal for the busiest spaces. Non-woven materials are breathable and much easier to remove for a quick room refresh. Paper is strictly reserved for the most delicate artistic High-quality wall prints.

B. Performance Coatings and Backings

Coatings like acrylic or PVC are applied to boost thewallcovering’s scrub resistance and overall lifespan. You will also select between traditional paste application or peel-and-stick backing for quicker deployment. These final layers greatly impact the product’s ongoing maintenance and how easy-to-clean wallpaper material is.

C. Fire Ratings and Certifications

Mandatory fire ratings and health certifications become supremely important in public or commercial spaces across the Middle East. Look for global standards like Class A ratings and verify the product contains no harsh Volatile Organic Compounds (VOCs)

6. Ink Science: Matching Ink Types (Latex, UV, Solvent) to Print Quality

The ink choice must match the substrate and the final performance requirements of the wall site. You shouldn’t overlook this absolutely critical chemistry component which defines the finish.

The printing industry now uses non-volatile solvent-free inks which provide better safety and superior lightfastness properties. The development of new printing materials protects your Bedroom wallpaper designs from the strong UAE sunlight that frequently occurs in this region. The quality of printing inks determines both the durability and color intensity of printed materials.

A. Latex Inks

Latex inks are water-based and contain polymer particles offering a flexible Durable wallpaper material finish. They are the favorite for digital wallpaper printing today. They dry instantly producing odorless prints a major advantage for sensitive indoor environments like homes or hospitals. Furthermore, they are celebrated for their eco-friendly profile.

B. UV-Cured Inks

UV inks are famous for their excellent color saturation and strong adhesion to non-porous materials like vinyl. This results in incredibly Long-lasting wall decoration with high-definition longevity.

C. Eco-Solvent/Solvent Inks

Older solvent technology used petrochemical bases giving strong colors but often released problematic VOCs during curing. Newer eco-solvent versions are safer but still can’t match the harmlessness of the latest latex and UV options. Always prioritize low-VOC options especially for Kitchen-friendly wallpaper designs.

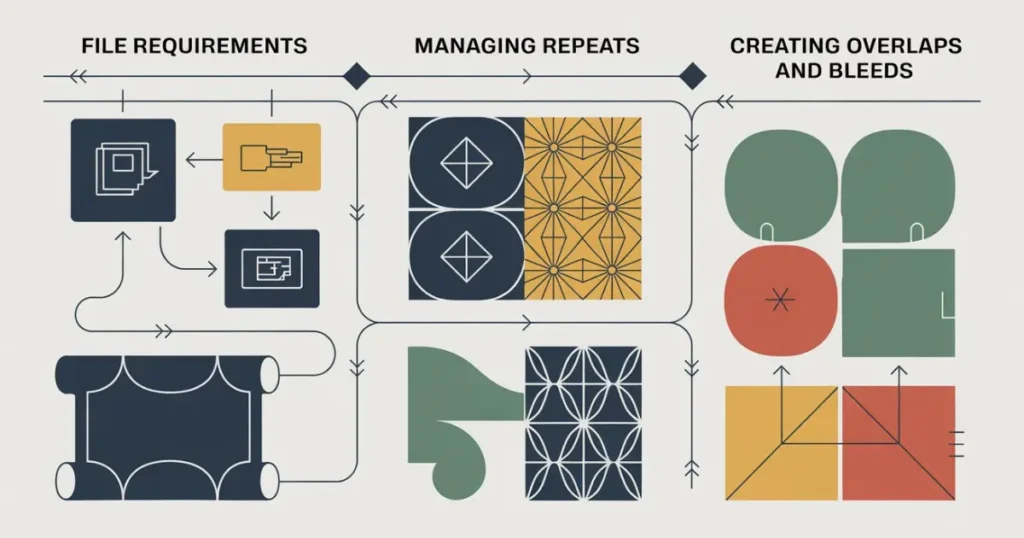

7. The Print Process Flow: Design File Preparation and Pre-Press Essentials

Before any ink hits the paper a whole sequence of preparatory steps called pre-press must be done perfectly. The final quality of your printed wallpaper is completely determined by the meticulous precision of the design file and color management. As the old adage goes, garbage in equals Wall décor solutions garbage out.

Ignoring these technicalities guarantees costly reprints and frustrating production delays especially when you import materials for Wallpaper Printing UAE projects. Successfully connecting your digital design to the colossal printing machine is a huge technical task. This stage needs expert attention to every last detail for Custom wall prints.

A. File Requirements

Your design files must have very high resolution usually 300 DPI for a sharp output. They must be correctly formatted in CMYK color mode for accurate printer reproduction. Submitting RGB files will cause significant color shift a common and easily avoided pitfall in digital printing projects. Always check your printer’s specifications first.

B. Managing Repeats

Wallcoverings depend on a precise pattern repeat that must align perfectly when installed on the wall. You specify whether your design is a straight match a half-drop match or perhaps a more complex random match before starting production. Improper repeat management creates an unhangable product without question.

C. Creating Overlaps and Bleeds

The installation process of printers requires a specific amount of overlap between printed edges and bleed areas at the roll’s borders. The small buffer zones function as protective areas which help prevent seam lines from appearing during the installer’s section trimming process. The technical specification ensures that Wallpaper installation services will achieve a professional finish.

8. Beyond Aesthetics: Quality Standards, Durability, and Eco-Friendly Trends

Quality is so much more than just looking good it also means the wallcovering’s strength and lifespan. You simply must demand rigorous performance benchmarks when selecting a supplier for your valuable wall décor. Ignoring these simple specifications is a major mistake leading to quick fading or structural failure. This section outlines the non-design factors you should always check.

Today’s consumers and designers increasingly want planet-conscious products and highly enduring finishes. The industry has quickly embraced sustainability offering solutions that minimize environmental harm without hurting resilience. This blend of long-term durability and ecological stewardship defines the leading Modern wallpaper trends globally.

A. Lightfastness and Washability

Lightfastness accurately measures the wallcovering’s resistance to fading when it gets hit by prolonged fierce sunshine. High ratings ensure your vivid colors won’t unexpectedly fade into dull shadows in a few months. Meanwhile Easy-to-clean wallpaper material is measured by scrub resistance determining how hard you can safely clean the surface.

B. The Sustainability Imperative (VOCs and Recycling)

The huge shift toward healthier interiors means minimizing Volatile Organic Compounds or VOCs is now absolutely paramount. Look for PVC-free substrates and water-based inks that greatly improve indoor air quality after installation. Many modern wallcoverings are also expertly engineered for easy end-of-life recycling. This helps create a personalized environment responsibly.

Conclusion: Choosing the Right Printing Technique for Your Project

Choosing the perfect wallpaper printing method truly requires balancing your artistic goals with commercial needs. Your final selection must successfully combine the required volume the design’s complexity and your exact budget constraints. It’s never just a creative whim it is a critical logistical and financial calculation you must do.

Whether you ultimately choose the handcrafted patina of traditional block printing or the incredible speed of modern digital technology you are now fully prepared. You understand the techniques the materials and the standards to ensure your next Wallpaper Printing UAE project is absolutely stunning and enduring. We wish you immense success in your Designer wallpapers in UAE endeavors.