Acrylic printing has become one of the most innovative methods for achieving contemporary, eye-catching visual displays in homes as well as for small business owners. In the past, this type of printing required expensive equipment and the expertise of professionals to complete successfully. Through the invention of compact, UV-based printers, there is now a simple way to produce high-quality results printing on acrylic substrates without the need for heavy machinery or expensive investments in specialized training for the operator.

By using acrylic, one achieves a beautiful finish that resembles glass but is lightweight and strong; therefore, acrylic printing is ideal for decorative items, signs, and many other creative projects. The popularity of prints using acrylic sheets at home is rapidly increasing; this is a result of consumers having total control over the final product, including its design, colour vibrancy, durability, etc., as well as being able to produce products with high-quality results. High-quality results are achieved with appropriate equipment used for UV printing. Once again, by utilizing the correct equipment, acrylic prints will produce vivid, saturated colors, excellent adhesion,, and professional quality.

What Is Acrylic Printing and Why It’s So Popular

Acrylic printing means placing ink directly onto acrylic sheets using UV technology. Acrylic, often called Plexiglas, looks like glass but feels lighter and safer. Most people love acrylic in the UAE because it is a very heat-resistant substrate and retains color well for many years. The end result when printed on acrylic using UV printers is also very bright and therefore appropriate for most home, office, and retail locations.

| Feature | Acrylic Printing |

| Visual finish | Glass-like clarity |

| Durability | High and long-lasting |

| Climate fit | Ideal for UAE heat |

| Popular uses | Signs, art, decor |

Types of Acrylic Sheets Used for Printing

Not all acrylic behaves the same. Acrylic sheets come in clear, frosted, and white finishes. Clear sheets allow light to pass through. Frosted sheets soften glare. White sheets give solid color output. Thickness matters too. Thin sheets heat faster. Thick panels stay flat. Choosing the right acrylic material for prints improves results and reduces errors.

| Acrylic Type | Best Use |

| Clear acrylic panels | Light effects, signage |

| Frosted acrylic | Privacy decor |

| White acrylic | Photo prints |

Can You Really Printing on Acrylic at Home?

Yes, you can. How to print on Acrylic at Home works when you use the right tools. Home setups handle small signs, art, and gifts. When it comes to larger commercial jobs, professional print shops fit the bill. Similarly, most artists and designers within the UAE start their print journey at home and progress into larger print shops at a later stage. Home acrylic printing saves time and gives creative control.

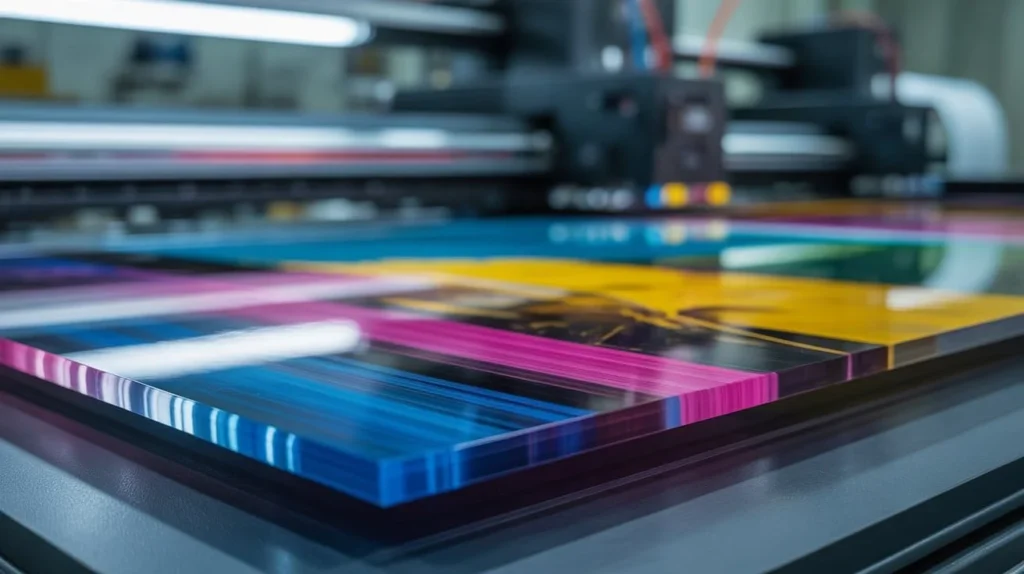

Tools and Equipment Needed for Acrylic Printing at Home

A UV flatbed printer is essential. Regular inkjet ink slides off plastic. UV-cured ink bonds to acrylic instantly. Design software controls layout and color. Cleaning tools matter too. Dust ruins prints. Stable power helps. These basics support reliable acrylic printing at home in apartments or studios.

| Tool | Purpose |

| UV flatbed printer | Prints directly on acrylic |

| White ink channel | Bright colors |

| Design software | Layout control |

How to Printing on Acrylic at Home Step by Step

It is important to respect each step of the process for a successful outcome when using UV printers on acrylic; rushing the process at any stage will likely cause errors throughout. Preparation always decides final quality in printing on acrylic.

Step 1: Clean the Acrylic

Always clean first. Acrylic attracts static. Static pulls dust. Use alcohol wipes. Dry gently. A clean surface helps UV acrylic printing last longer.

Step 2: Prepare Your Design

Design files need clarity. Use high resolution. Plan light areas carefully on clear sheets. Smart planning improves acrylic photo printing results.

Step 3: Set Up the Printer

Place the sheet flat. Secure thin panels. Warping causes head strikes. Good alignment protects your acrylic UV printer.

Step 4: Select Material and Print Settings

Choose acrylic in software. Adjust quality based on purpose. High-quality uses more ink but looks premium. Settings guide acrylic sheet prints’ success.

Step 5: Set the Ink Mode

White ink matters. Use white under CMYK on clear sheets. Skip white for transparency. Layer modes support 3D texture printing effects.

Step 6: Start Printing

Start the job. UV light cures ink instantly. Touching is safe right away. That’s the power of printing directly onto acrylic.

Best Printer and Ink Options for Acrylic Printing in Dubai

A proper machine makes learning easier. Look for adjustable height. White ink support is mandatory. Compact models suit homes. Quality ink resists fading. The right setup improves print ink on acrylic durability in UAE conditions.

| Feature | Why It Matters |

| Adjustable height | Handles thickness |

| White ink | Color accuracy |

| UV lamp | Instant curing |

Why UV Printing Is the Best Method for Acrylic

UV printing wins because speed meets quality. Ink cures on contact. Colors stay vivid. Surfaces resist scratches. Clear acrylic printing looks clean and modern. For UAE homes and shops, UV printing handles sunlight better than other methods.

Common Mistakes to Avoid When Printing on Acrylic

Skipping white ink dulls colors. Dust causes bumps. Wrong height scratches prints. Heat warps thin sheets. Learning How to Printing on Acrylic at Home means respecting these limits before scaling.

Creative Uses of Acrylic Printing for Home and Business

People print wall art. Offices print signs. Shops print displays. Makers print gifts. Custom acrylic prints elevate spaces without heavy frames. Acrylic adapts to branding and personal style easily.

| Use Case | Result |

| Wall art | Modern decor |

| Signage | Professional look |

| Gifts | Personal value |

Home vs Professional Acrylic Printing Services in UAE

Professional services offer scale. Small runs fit homes. Large panels fit studios. Many UAE creators test designs at home, then outsource final batches. That balance maximizes durable acrylic prints and profit.

Final Thought

How to Printing on Acrylic at Home is no longer complex. With UV tools, smart setup, and patience, anyone in the UAE can create sharp, lasting prints. Start small. Learn fast. Let acrylic carry your ideas forward.

FAQs

Correct! You can print onto acrylic using UV prints methods. The UV ink bonds directly to the surface creating sharp images with high durability.

No. UV printed acrylic does not melt or burn the acrylic because the UV ink cures immediately and therefore does not create heat that could compromise the material.

Yes, professional printing of acrylics tends to be much more expensive than at-home UV printing options.

No. A laser printer cannot print onto acrylic because toner will not adhere and the heat created by the laser may damage the plastic.

Materials like acrylic, glass, metal, and ceramics should not be heat pressed. High heat can warp, crack, or discolor them. UV printing is a safer alternative.

Using UV prints, UV DTF film or an adhesive vinyl you can transfer your design onto acrylic. The most durable method of securing your design is through the use of UV printing.