The UAE has experienced a transformation in art and photography and commercial signage production through metal printing technology during the recent years. The modern technology produces durable visual displays through its three advanced methods which include UV laser engraving on metal and dye sublimation processing.

The printing method produces vibrant colors which maintain their clarity while being resistant to fading and moisture and heat exposure in the UAE’s extreme weather conditions. aluminum prints enables creators to display their work on strong durable surfaces which produce realistic photo-quality images that outlast conventional paper prints for both home decoration and business branding needs.

Different Types of custom metal prints Methods

The production of metal prints happens through multiple methods which employ distinct heat and pressure transfer or ink sublimation technologies. The printing process involves direct aluminum printing and sublimation paper with polymer coating for image transfer.

Th printing labs in UAE conduct research on heat press and photo lamination on metal and fine art printing for industrial and decorative uses. The different printing methods produce two distinct surface finishes which include glossy and matte effects that generate unique visual outcomes.

UV Printing on Metal

UV printing on metal stands as a leading technique which Dubai and other UAE areas widely adopt. The process of metal printing with Epson F series printers and Epson OEM inks directly applies designs onto aluminum steel and copper metal substrates.

During printing, ultraviolet light instantly cures the ink on the high-grade aluminum surface. The result? Scratch-resistant materials and UV resistant coating that offer photo preservation and UV protection even under the harsh Gulf sunlight.

Laser Engraving and Etching on Metal

The process of laser engraving on metal uses high-energy beams to vaporize surfaces which results in detailed designs. The UAE creative market benefits from this method for creating signage and gifts and industrial labels. The exact nature of this technique enables users to achieve 3D effect coating and photo-realistic finishes.

Many labs in the UAE prefer this method for high-definition image printing, vibrant and crystal-clear colors, and photo preservation. The prints resist fade resistance, humidity, and maintain long-lasting photo panels perfect for both home and commercial interiors.

Sublimation Printing on Metal

The dye sublimation process involves printing images on sublimation paper before transferring them to ChromaLuxe aluminum panels through heat press technology. This allows the sublimation ink to turn into gas and bond with the aluminum metal substrate.

Many labs in the UAE prefer this method for high-definition image , vibrant and crystal-clear colors, and photo preservation. The prints resist fade resistance, humidity, and maintain long-lasting photo panels perfect for both home and commercial interiors.

| Sublimation Printing Features | Description |

| Material Type | Chroma Luxe aluminum panels |

| Ink Type | Sublimation ink / Epson OEM inks |

| Transfer Medium | Sublimation paper |

| Finish Options | Glossy and matte finishes |

| Durability | Fade resistance & moisture protection |

Heat Transfer and Screen Printing on Metal

The heat press printing method through heat and pressure transfer creates powerful bonds between ink and metal substrate coating. The technique works best for promotional signs and industrial labels and nameplates which UAE businesses frequently use.

The process of screen printing metal requires inkjet printers with conversion and polymeric amides and copolymers for surface bonding. The combination of petroleum distillates with this process enables better ink absorption and higher ink capacity substrate which produces clean and sharp designs.

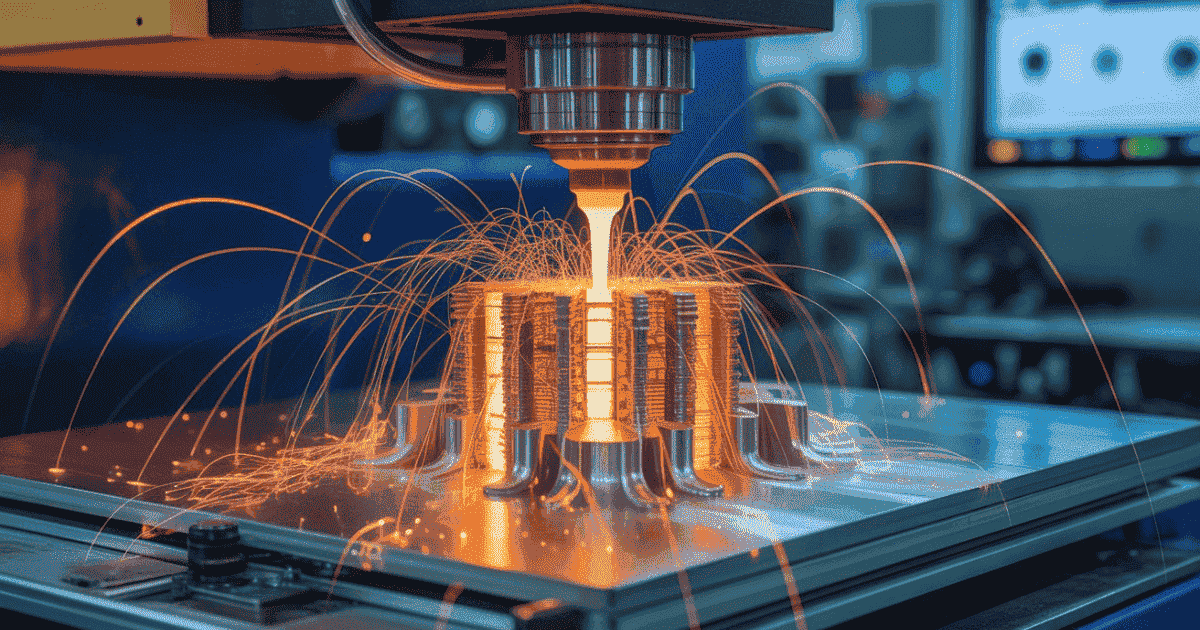

3D Metal Printing Technology

In recent years, 3D metal printing technology has transformed how industries in the UAE manufacture products. This method builds layers using ink sublimation technology or powdered metals fused by lasers to create complex forms.

Many architecture and automotive firms in Dubai now rely on fine art and 3D metal prototypes for high-end design work. These prints often feature polymer coating and UV protection for long-lasting strength and elegance.

Best Materials and Surfaces for Metal Prints

The selection of base material plays a crucial role in the process. The UAE metal printing labs primarily utilize high-grade aluminum together with copper metal substrate and brass metal substrate and steel metal substrate for their operations. The different metal surface finishes become available through these four materials.

The ChromaLuxe aluminum panels provide photographers with their best option because they weigh less and resist UV light while producing authentic photo results. Industrial-grade aluminum provides maximum outdoor durability because of its exceptional strength.

Popular Metal Printing Applications

The UAE uses metal printing technology and processes to create digital face mounts and home décor items and fine art pieces and architectural signage. Designers choose metal photo prints because they offer both bright colors and clear definition and they can be finished with glossy or matte effects.

Companies use photo lamination on metal and heat press printing for office branding and exhibitions. Artists use fine art printing on high-grade aluminum for photo preservation, ensuring their work resists time, dust, and humidity.

Choosing the Right Machine for Home or Business

The selection of a metal printing machine requires evaluation of its dimensions together with its printing precision and its ability to work with different ink types. The Epson F series printers serve as dependable choices for small businesses that need to print UV designs on metal while using heat press techniques.

Industrial-grade aluminum printers with high ink capacity substrate and polymer coating technology are the preferred choice for professional metal printing labs. The systems operate best with Epson OEM inks to produce consistent color quality and durable results.

Maintenance and Care of Metal Prints

The correct maintenance methods help extend the product lifespan. A microfiber cloth used for regular cleaning of metal photo prints helps prevent dust accumulation on the surface. The polymer coating requires careful application of acetone or denatured alcohol for stain removal because improper use can result in damage.

Follow these maintenance tips for metal art—avoid abrasive cleaners, use mild soap for stain removal on metal prints, and keep prints away from direct sunlight to preserve fade resistance and life-like photo finish.

| Cleaning Method | Recommended Tool | Purpose |

| Regular Dusting | Microfiber cloth | Removes particles |

| Deep Cleaning | Acetone or denatured alcohol cleaning | Removes oil and fingerprints |

| Preservation | UV resistant coating | Protects color and texture |

Conclusion

The selection of technology and process depends on your specific requirements. The combination of dye sublimation printing on ChromaLuxe panels delivers artistic prints with both vibrant colors and crystal-clear clarity. The combination of UV provides businesses with the most durable solution for commercial signs and branding needs.

The UAE market experiences ongoing development through advancements in ink sublimation technology and polymer coating and high-grade aluminum which enable both personal and commercial users to create permanent fine art prints and photo preservation.

FAQ

How is metal printing done?

Metal printing is done by transferring digital images onto specially coated sheets using dye-sublimation or UV technology, creating vibrant, durable, and scratch-resistant prints.

What is metal printing called?

The process of metal printing receives three different names which include metal photo printing and metal art printing and dye-sublimation on aluminum. The most widely used technique for metal printing involves dye-sublimation on aluminum which people refer to as aluminum photo prints.

Can I 3D print onto metal?

The process of 3D printing uses Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) to build solid metal objects through the fusion of metal powder layers.

How can you print on metal?

The process on metal surfaces involves four different techniques which include UV and dye-sublimation and screen printing and laser engraving for achieving different design effects.

What kind of printer can print on metal?

The range of metal photo printing equipment includes UV flatbed printers for direct color printing and sublimation printers with coated metal sheets and laser engravers for etching and marking metal surfaces.